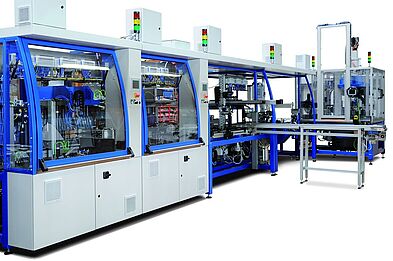

Individual solutions thanks to various assembly platforms.

HAHN Automation Group GmbH offers a wide portfolio of assembly platforms to design and manufacture individual customer solutions despite standardized concepts. Depending on the customer's requirements for the production process and the level of automation, one of the three platform concepts is used as the basis for the production line. Based on this, stations and processes are individually adapted to the customer's production.

MasterCell. 100% flexible, 100% adapted to customer requirements.

Fast product start-ups and ever shorter product life cycles require a flexible assembly. HAHN Automation Group GmbH meets these challenges with the modular assembly cell MasterCell. Individual modules enable fast relocation and recommissioning. Solid base frames, plug-in installations and constructions that meet all logistic requirements enable global rollouts and relocations.

Due to a consistent design in grid dimensions HAHN Automation Group GmbH can reduce engineering significantly and focus on the process. Thereby the use is particularly flexible, from robot integration to manual loading to the connection with transfer technology. MasterCell is designed as a specific process cell or used as cleanroom version MasterCell cleanroom.

LEAN. The intelligent solution for efficient production.

The LEAN concept of HAHN Automation Group GmbH guarantees customers a smooth production without downtimes. A standardized 600 mm / 800 mm / 1000 mm grid structure ensures an optimal utilization of the available production space. LEAN systems can be flexibly combined and interlinked and thus enable an optimized production flow. The inspection of the article to assemble can be done per station to ensure that only OK parts pass through the entire production process. For an error-free production.

APTUS. Precisely well-balanced for linear assembly processes.

APTUS (from the Latin for "precisely adapted, suitable") is a modular assembly system for semi-automatic and fully automatic production solutions that offers an excellent combination of automated and manual process sequences. Despite the standardization, the system concept is adapted to the customer's needs to ensure an optimal production process. Thus, each customer receives exactly the technical equipment required for the product in mind, enabling a high degree of economic efficiency.

HAHN Automation becomes HAHN Automation Group. You can find information about the re-branding here:

more info