Test & Inspection. Trust is good, testing is better.

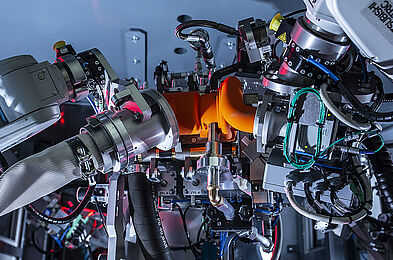

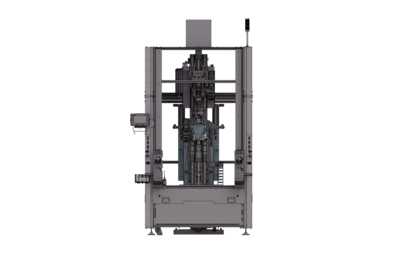

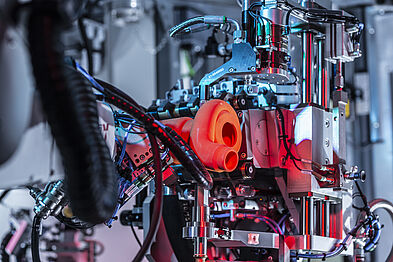

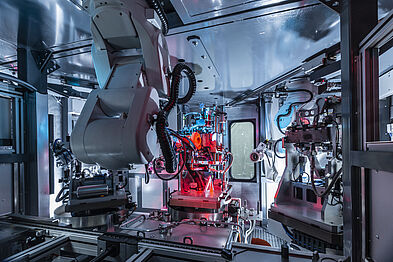

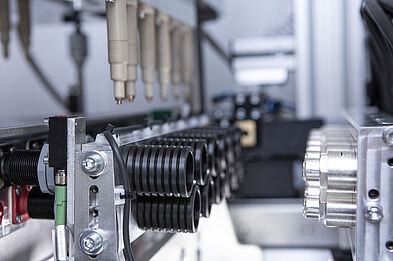

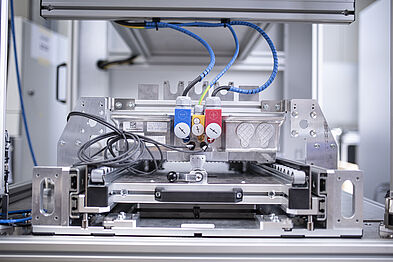

Global developments and innovations increasingly demand standardized and intelligent manufacturing solutions. HAHN Automation Group GmbH has developed integrated, comprehensive solutions, from assembly and processes to complex test engineering. The concepts of the test systems are always adapted to the needs of the operators. For this purpose HAHN Automation Group GmbH continuously develops its own test processes and can continuously improve and optimize them.

HAHN Automation Group GmbH's test engineering is not only adapted to the latest state of technology, but also designed to be particularly efficient. The test processes are real time capable and based on PC-supported systems. The user interface of the test application is fully integrated into the plant control system and adapted to the needs of the production. In addition, it is possible to access and manage all information relevant for the test engineer in special menus. Integration of test systems and interfaces of all common bus systems for the control of actuators in the automobile are a matter of course for HAHN Automation Group GmbH.

HAHN Automation becomes HAHN Automation Group. You can find information about the re-branding here:

more info